Opening in the fall of 2026, the Design and Innovation Studio will be located on the first floor of Stadler Hall.

The studio will house machine and wood shops, 3D printer stations, VF-2 CNC machine equipped with robot, lathe and milling machines, wind tunnel for fluids and aerodynamics studies, laser cutter, and MTS universal testing machine for product design, manufacturing and research, 24 multi-purpose workbenches for student’s experiential learning projects, senior design courses, industry partnerships and engagements.

The Mechanical Characterization Laboratory houses a comprehensive suite of equipment for evaluating material behavior across a wide range of applications, including aerospace, automotive, biomedical, and energy sectors. The lab enables material characterization across multiple length scales, from microscale features to bulk mechanical properties.

The facility is accessible to students upon completion of required safety and equipment training and directly supports instruction in Mechanics of Materials (ENGR 2332L) and Properties of Materials (MENG 3340).

Beyond coursework, the lab serves as a critical resource for faculty-led and industry-sponsored research. The laboratory plays a pivotal role in senior capstone design projects, where students leverage both mechanical testing capabilities and adjacent wet-lab facilities equipped with certified chemical hoods to iteratively test and refine their designs throughout the academic year.

Designed as a shared research hub, the Mechanical Characterization Laboratory will continue to expand as new faculty join the School of Engineering and contribute specialized equipment aligned with their research programs. In addition, the lab functions as a regional resource, offering fee-for-service access to industry partners and academic institutions to support testing, maintenance, and technical staffing. The facility is supported by a full-time laboratory technician to ensure safe operation, equipment readiness, and high-quality experimental outcomes.

Examples of equipment available in the Design and Innovation Studio

VF-2

The VF-2 is used in aerospace, automotive, medical device manufacturing, in addition to general machining. The VF-2 in the design studio is equipped with additional features such as tool changer, programmable robot, wireless intuitive probing system, chip auger, and high-speed machining for advanced manufacturing. Its specifications include: (x-, y-, z-axis - 762 x 406 x 508 mm), 40 taper, 30 hp vector drive, 8100 rpm, direct-drive, 20-station carousel tool changer, 25.4 m/min rapids, power-failure detection module, 1 GB program memory, 15″ color LCD monitor, USB port, Ethernet, memory lock key switch, rigid tapping and 208-liter flood coolant.

South Bend Lathe

Lathe - SB1114F 13" x 30" EVS Lathe with Fagor DRO: The Gearhead Lathe is driven by a 5 HP motor with electronic variable speed to control spindle speeds between 100–3000 RPM. A factory-installed Fagor two-axis digital readout displays the positioning of the carriage and cross slide.

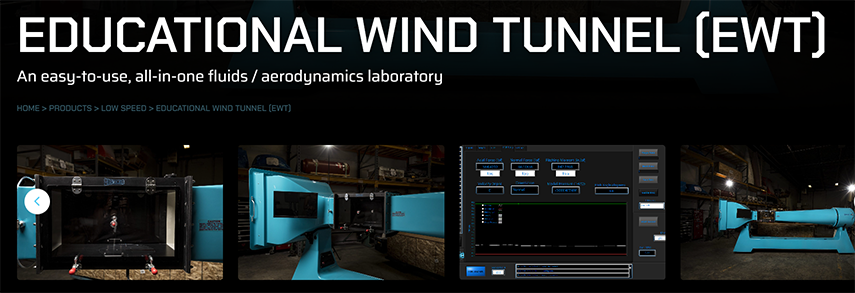

Wind Tunnel

Test Section Dimensions: 12”x12”x24” (30.5cm x 30.5cm x 61cm) • Airspeed Range: 10 mph (4.5 m/s) to 145 + mph (65 + m/s) • Turbulence Level: less than 0.2%. • 9.5:1 contraction ratio Static Pressure Ring • Access to test section static pressure for non-intrusive q/V measurements • Consists of four pressure ports – one on each wall just prior to test section entrance w/ manifold Test Section