Lab inspections ensure compliance with regulations, standard safety procedures and practices, raise safety awareness, and reinforce a positive safety culture. EHS provides lab safety inspections however, internal lab inspections are recommended weekly or monthly by lab personnel. Internal lab inspections provide opportunities for training and give personnel the opportunity to ask question, raise concerns and help identify current and future lab safety needs. To perform an internal lab inspection, lab personnel can use the EHS Lab Inspection checklists for guidance as well as the information provided here.

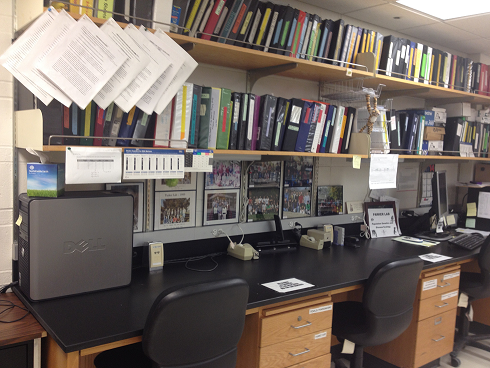

Start the inspection by evaluating the labs housekeeping and accessibility. Determine the overall cleanliness of the lab. The lab should appear clean, organized and professional. Ensure the walkways are clear and free from tripping hazards. Confirm that people can walk safely through the lab and can easily reach critical equipment such as safety showers, eye wash stations, fire extinguishers, first aid kits, fire blankets, spill kits and emergency exits. Make sure that everyone is aware of where these safety features are located. The lab should keep the first aid kits and spill kits stocked. If there is an eyewash bottle in the lab, make sure they are in good condition and in date.

Next evaluate the engineering controls used in the lab. These includes fume hoods and biological safety cabinets (BSC). The fume hood and or BSC should be within a year of the last certification. Check to see that the correct sash height is indicated for proper usage. The performance and effectiveness of the fume hood or BSC is greatly reduced if operated outside of approved conditions. Never leave open, uncapped or broken bottles of agent in the fume hood or BSC.

Assess the personal protective equipment or PPE used in the lab. This includes items such as lab coats, safety goggles, and gloves. PPE should be in sufficient quantity, in good condition, available to all personnel, and appropriate for the designated task. Safety Data Sheets list PPE requirements and the US Department of Energy has a Glove Selection Guide.

Consider overall lab hygiene practices. Avoid loose clothing and hair styles. Protect your feet by wearing closed toes shoes. Do not eat, drink, apply cosmetics or manipulate contact lenses in the lab. These are common routes of exposure that can be easily avoided with good lab hygiene.

Inspect the labs chemical storage and compressed gas storage. Chemicals should be stored by compatibility and hazard class to prevent unwanted chemical reactions. Hazardous chemicals should be stored below eye level and off the floor. Gas cylinders and flammable chemicals should be stored away from potential ignition sources. Flammable and combustible liquids should be stored in a flammable storage cabinet. Never store flammables in a refrigerator or freezer unless it meets NFPA guidelines for safe flammable storage. Store gas cylinders secured in an upright position with the label clearly visible. Segregate strong acids and bases and store in a secondary container. Be aware of any peroxide forming or other time sensitive chemicals in the lab and check usage dates. Chemical storage on bench tops or on the floors should be avoided. Secondary chemical storage that is not used by the end of the work day needs to be labeled with the chemical name, concentration (if applicable), and any associated hazards. Make sure all lab members are familiar with the new Globally Harmonized System for Hazard Communication.

Appraise lab signage for flammables, corrosives, “No food or drink”, and PPE requirements. Emergency contacts should be posted. Other records the lab should maintain include SOPs, internal lab safety training, chemical inventory, and SDSs.

Records for Unwanted Materials Containers should include the chemical name and accumulation start date. Keep flammable and corrosive unwanted materials separate. Keep metal bearing materials separated from other unwanted materials. Do not leave unwanted materials collection containers uncapped. Notify EHS to pick up unwanted materials 5 months from the accumulation start date.

If the internal lab inspection raises any questions or concerns, call EHS for help.